|

Sales:Butyl

ether (epoxy diluent D-501, BGE )----

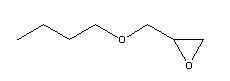

(butoxymethyl)-Oxirane;Butyl epoxy propyl ether

660;1-butoxy-2,3-epoxy-propan;1-butoxy-2,3-epoxypropane;2,3-epoxypropyl

butyl ether;3-butoxy-1,2-epoxypropane;ageflex

bge;bge;butoxymethyloxirane;butyl 2,3-epoxy propyl ether

|

Molecular formula: C7H14O2

Molecular Weight: 130.18

Boiling Point: 166 ℃

1. brief introduction:

501 epoxy resin active diluent chemical name for the butyl ether of

propylene oxide and epichlorohydrin by the Department of butanol

etherification open-loop re-oxidation by the closed-loop system of a

glycidyl-type epoxy diluent molecules containing live ether key and

epoxy, epoxy resin dilution effect, curing time involved in curing to

form a homogeneous system, are commonly used epoxy resin reactive

diluent.

Traits

Description: colorless transparent liquid. Relative density 0.915,

boiling point 164 ℃, refractive index 1.420, flash point 59 ℃. Soluble

in acetone; benzene; alcohol, insoluble or hardly soluble in water.

Production methods: by the alcohol and epichlorohydrin as raw materials,

was synthesized by two steps. Specific process is: 32kg to 267kg and

butanol concentration of 96% of concentrated sulfuric acid reactor add,

stirring, heating to 55 ℃, epichlorohydrin dropwise 324kg, temperature

control at about 55-60 ℃ increasingly 4h, and then at 60-65 ℃ insulation

2h. Then, cooling to 45 ℃, slowly add four chloride with n-butanol

mixture (5kg tin tetrachloride in n-butanol soluble 5kg), and then heat

at 60-65 ℃ reaction 4h, reaction after vacuum distillation recovery

unreacted epichlorohydrin and of n-butanol until the temperature reaches

85-95 ℃, under vacuum 93.1kPa epichlorohydrin and alcohol-free until

steamed out. Be Epichlorohydrin-butyl ether. Response to the

above-mentioned materials to cold 30-35 ℃, dropping 30% of the sodium

hydroxide concentration of 432kg, plus about 4h End, and then warming to

35-40 ℃ and heat reaction 3h, and then add pure benzene under stirring

at temperature to release out saline and alkaline, and then washed so

that pH of about 6.5-7. Release washing water, atmospheric warming from

benzene, until the liquid temperature to 140 ℃, then cooled discharge.

Two-step to the total yield of about 95% butanol.

Purposes: the goods can be used for bisphenol A epoxy resin reactive

diluent. Toxicity in small and easy to use. And can improve some

properties after hardening resin, such as impact strength.

2. molecular formula: C7H14O2

Molecular Weight: 130.18

3.structural formula

CAS

:2426-08-6

4.traits:

Colorless transparent liquid, with

smell, the proportion of 0.87 (low toxicity).

5.indicators:

Epoxy value (eq / 100g): ≥ 0.53

Viscosity (25 ℃): 2 ~ 5mpa.s

Organic chlorine (equivalent / 100g): ≤ 0.02

Inorganic chlorine (equivalent / 100g): ≤ 0.005

Flash ignition (℃):> 150

6.use:

Can

be widely used in electronics, electrical, electromechanical,

mechanical industry, to reduce viscosity of epoxy is suitable for

potting, casting, impregnating applications such as technology, can

also be used for adhesives.

Friday, storage, transportation and Cautions:

1. Such products as non-dangerous goods, as a general storage and

transportation of chemicals, product packaging, see barrels of

storage period.

2. Please light, ventilation, dry storage environment.

3. This product is in use, the packaging of the goods remaining to

tightly to prevent moisture absorption.

7.packaging specifications

Plastic packaging for 200kg in metal containers. |